Your cart is currently empty!

Categories

Recent Posts

- Beyond the Structure: A Story of Transatlantic Trust and Craftsmanship

- Representing Nations: The Art of Pavilion Stand Building at CIIE

- Why International Brands Choose Local Chinese Booth Builders Over Global Competitors

- 🌏 The 2026 Guide to Choosing the Right Trade Show in China: A Roadmap for Foreign Exhibitors

- Why International Agencies Choose Panda Expo China as Their White-Label Production Partner?

Archive

Tags

Access the Exhibition Venue for Work During Setup Period in China Air Cargo China BEIJING booth construction Booth Setup in Chinese Exhibition Venues CHINAPLAS CIPS Custom Booth Design custom exhibition stand builders Double Deck Exhibition Stand exhibition exhibition booth construction exhibition booth design exhibition booth in qingdao exhibition stand builder China Exhibition Stand Construction exhibition stand construction for poland pavilion EXHIBITION STAND DESIGN exhibition stand designers and builders exhibition stand in qingdao expo stand builders expo stand design FHC China Booth Construction Guangzhou Exhibition Booth Construction Guangzhou Exhibition Booth Construction Services HONG KONG Our Valued Brand Partners Panda Expo Panda Expo China SHANGHAI singapore tradeshow list 2026 Sports Events in China tradeshow in guangzhou tradeshow in india tradeshow in india 2026 tradeshow in japan tradeshow in shanghai tradeshow in vietnam tradeshow list in Hong Kong tradeshow list in indonesia 2026 tradeshow list in shanghai china 2026 tradeshow list in south korea TRADE SHOW LIST 2025 in china Vinexpo Asia Hong Kong 2026 Exhibition Stand Construction we are hiring

Social Links

🍽️ Food Exhibition Booth: A Highly Integrated System Project

The uniqueness of food-related booths lies in the fact that they are not only about “looking good” but also about ensuring safety and efficiency under heavy operational loads. In essence, they function as both a temporary restaurant and an industrial kitchen.

1. Energy & Utilities

- Water Supply & Drainage: Commercial-grade sinks and high-frequency dishwashing equipment require stable water pressure and complex drainage layouts (with anti-clogging measures).

- High-Load Power Distribution: Cooking, refrigeration, and heating appliances are all high-power. Accurate load calculations and multi-circuit distribution are essential to prevent outages.

2. Commercial Kitchen Equipment Integration

- Hot Processing Equipment: Steam ovens, induction cookers, microwaves, grills.

- Cleaning Equipment: Automated dishwashers and glass washers.

- Refrigeration & Beverage Systems: Commercial refrigerators, freezers, and professional coffee machines.

3. Specialized Labor & Trades

- Plumbers: Responsible for water supply sealing and drainage systems.

- Electricians: Handle high-power distribution and appliance connections.

- Equipment Engineers: Install, calibrate, and maintain dishwashers, coffee machines, and exhaust systems.

4. On-Site Staffing & Operations

- Core Catering Team: Experienced chefs and waitstaff for live operations.

- Media Team: Professional photographers and videographers to capture events for brand promotion.

5. Digital Infrastructure

- Network Support: Food booths often involve QR code ordering, live streaming, and cloud-based order management. Stable Wi-Fi coverage and dedicated IT staff are critical.

📊 Complexity Overview Table

| Dimension | Core Requirement | Key Risk Points |

|---|---|---|

| Water / Power | High-power electricity, continuous water supply | Leakage risks, overload outages, drainage odors |

| Equipment | Kitchen appliances, exhaust systems | Insufficient cooling causing breakdowns, non-compliant smoke emissions |

| Personnel | Chefs, engineers, media, IT | Inefficient coordination, overlapping workflows |

| Safety | Food safety, electrical safety, fire prevention | Fire hazards, slippery flooring |

💡 Recommendations for Spanish Design Companies

When outsourcing such complex projects to Chinese exhibition stand contractors, it is advisable to include the following attachments in the technical RFP:

- Maximum Instantaneous Power Load

- Water Supply & Drainage Node Diagram

- On-Site Exhaust & Ventilation Plan

Note: For complex food booths, a detailed on-site management SOP can further ensure contractors respond quickly to unexpected issues during the exhibition.

🍽️ On-Site Management SOP for Food Exhibition Booths

1. Pre-Exhibition Preparation

- Energy & Utilities Check

- Electricians verify total load calculations and multi-circuit distribution.

- Plumbers test water pressure and drainage flow, ensuring anti-clogging measures.

- Equipment Testing

- Engineers run trial operations of ovens, dishwashers, coffee machines, and exhaust systems.

- Refrigeration units checked for stable cooling.

- Safety Setup

- Fire extinguishers, fire blankets, and emergency exits marked.

- Conduct a short emergency drill for staff.

2. Daily Operations During Exhibition

- Energy Monitoring

- Electricians monitor power meters every 2 hours.

- Plumbers inspect drainage points at least twice daily.

- Equipment Inspection

- Refrigeration temperatures logged every 2 hours.

- Dishwashers and coffee machines checked after peak service times.

- Workflow Coordination

- Clear separation of zones: Kitchen, Service, Audience.

- Staff movement mapped to avoid cross-traffic.

3. Emergency Response Protocols

- Power Failure

- Switch to backup circuits immediately.

- Electricians investigate and restore main supply.

- Water Blockage

- Activate emergency pumps.

- Plumbers isolate and repair affected drainage nodes.

- Equipment Breakdown

- Engineers prioritize refrigeration and cooking equipment to maintain food safety.

- Fire Hazard

- Cut power instantly.

- Use fire extinguishers and initiate evacuation.

4. End-of-Day Procedures

- Cleaning

- Deep clean all kitchen equipment.

- Sanitize food preparation areas.

- System Shutdown

- Disconnect water and power supply safely.

- Daily Review

- Record incidents, energy peaks, and workflow issues.

- Share findings with management for continuous improvement.

5. Post-Exhibition Wrap-Up

- Equipment Dismantling

- Engineers disassemble appliances carefully for reuse.

- Utility Disconnection

- Plumbers and electricians remove connections per site regulations.

- Final Report

- Document all incidents, responses, and recommendations for future projects.

-

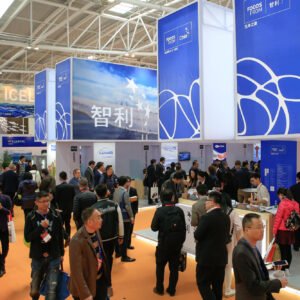

chile pavilion expo stand construction in China Fisheries & Seafood Expo (CFSE)

argentina pavilion expo stand construction in Sial China shanghai

allana exhibition stand construction by panda expo china

poland pavilion @sial china 2025

allana exhibition stand construction in vietnam

kazakhstan pavilion expo stand construction in aguafood beijing

India Pavilion stand construction at China Fisheries & Seafood Expo (CFSE)